To ensure that your weighing scales or balances are weighing correctly we recommend that they are checked with calibration weights regularly. The frequency of the checks should depend on how important the measurement is to your product or process and what the implications would be if the weighing equipment was out of tolerance. You will probably have a weighing company calibrating your weighing equipment six monthly or annually but this only ensures that the scales are correct at the time of certification but if the weighing results are important to you then we recommend additional checks to ensure that any damage or a fault has not caused an calibration error. Even a poorly fitting protective cover can cause a significant weighing error that may not be obvious without checking with weight calibration

Stainless steel test weights / calibration weights for balances with a 0.01mg or 0.1mg resolution

Stainless steel calibration weights / test weights for balances with a 0.1mg or 1mg resolution

Stainless steel test weights / calibration weights for balances with a 1mg to 0.1g resolution

Stainless steel test weights / calibration weights for balances with a 0.1g or 1g resolution

Brass test weights / calibration weights for balances with a 0.1g or 1g resolution

Cast iron test weights / calibration weights for scales with a resolution of 1g or more.

Cast iron test weights for proof load tests or for calibration of low accuracy scales.

Test weights for various testing, calibration and counterbalance uses. From 1g to 2000g.

Test weights for various testing, calibration and counterbalance uses. From 50g to 200 kg.

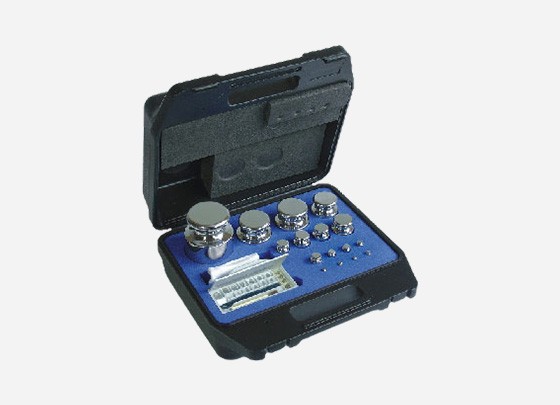

E2, F1, F2 and M1 standard stainless steel and brass calibration weight in standard box sets. From 1000 mg to 11 kg sets.

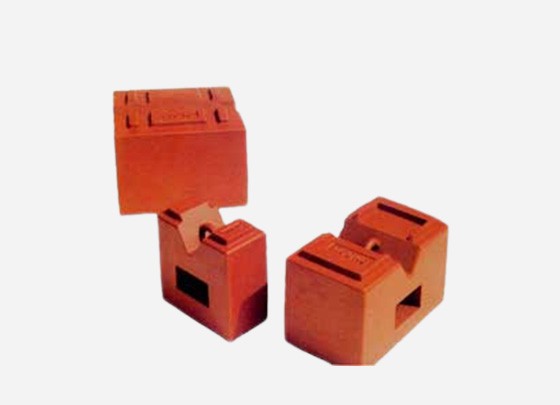

High quality cast iron stackable forklift block weights. Sizes from 100 kg to 1000 kg.